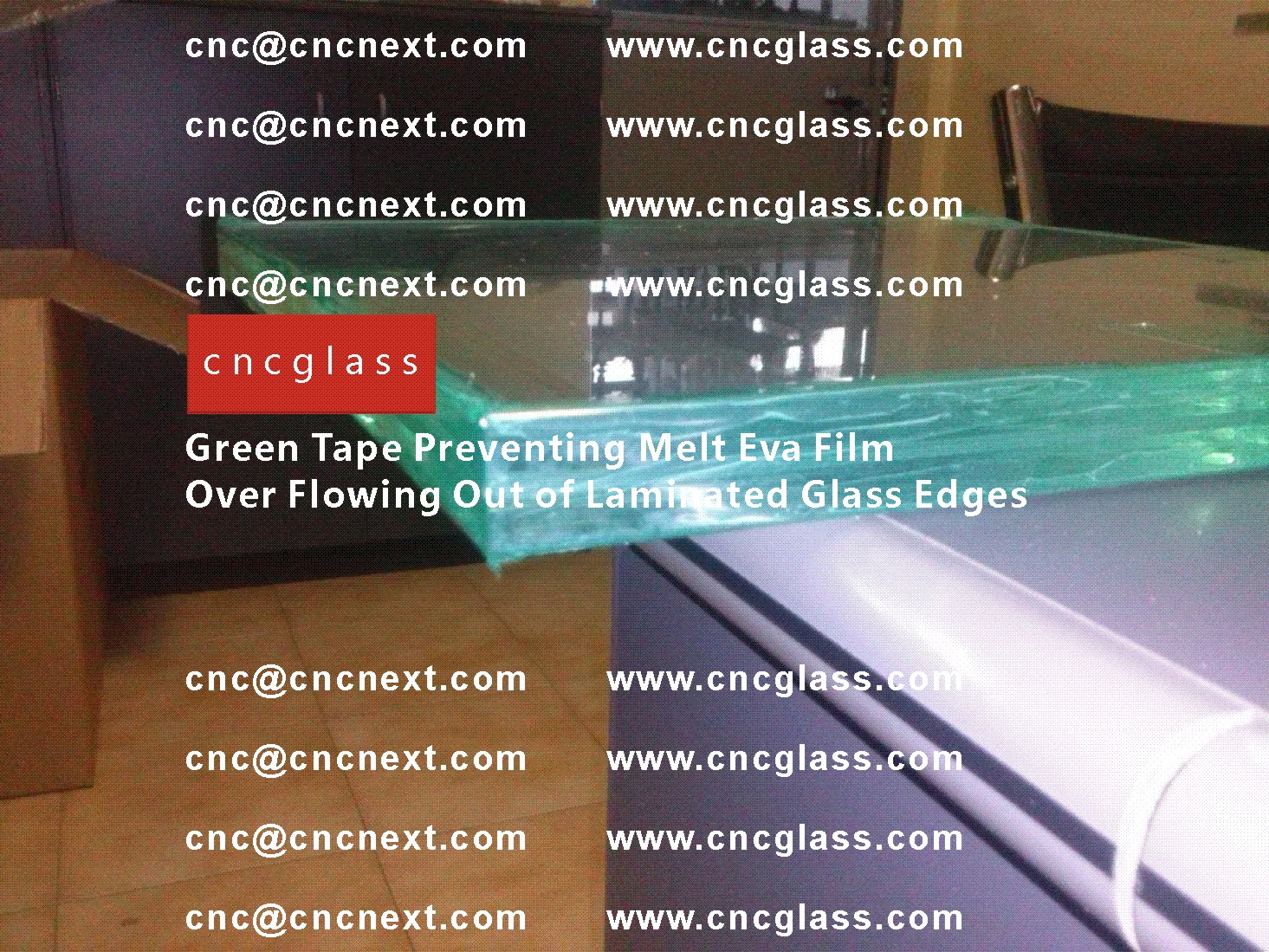

Green Tape Preventing Melted Eva Film Over Flowing Out of Laminated Glass Edges in the Oven

GREEN TAPE is to perfectly prevent the melt EVA FILM overflowing through laminated glass edges in the oven when heating(the GREEN TAPE is High temperature resistance).

What is the specifications of CNC GREEN TAPE?

25mm*66M/roll

30mm*66M/roll

35mm*66M/roll

40mm*66M/roll

50mm*66M/roll

If we use the CNC GREEN TAPE to seal the edges of pre-laminated glass to prevent the exit out of the EVA in the glass laminating oven, will the GREEN TAPE prevent the de-airing vacuuming? do we need to make some holes on the CNC GREEN TAPE for vacuuming the air out?

It depends. If you don’t make holes on the CNC GREEN TAPE, and you make EVA laminated glass successfully without bubbles, then you don’t need to make holes on the CNC GREEN TAPE, so you can get the cleaner result of the edges of the final laminated glass. But if you don’t make holes on the GREEN TPAE, but you face bubbles in the corners or edges of the laminated glass, then it’s better you make some holes on the CNC GREEN TAPE to help pre-laminated glass vacuuming.

Does CNC GREEN TPAE leave glues on the glass?

NO! No left remains of CNC GREEN TAPE on glass surface after peeling off. CNC GREEN TPAE can stand continuously heating more than 180℃with strong tear resistance.