Ethylene Vinyl Acetate EVA interlayer film for laminated glass, packing, loading container

Three Terminologies of Glass Laminating EVA Ethylene Vinyl Acetate Interlayer Film

By Peter Lin

1.

Cross-links Reaction:

Simply Speaking:

Cross-links Reaction is the key for the tensile strength, impact resistance, penetration resistance, and the thermoset properties of Glass Laminating EVA Ethylene Vinyl Acetate Interlayer Film.

Professional Introduction:

Cross-links are bonds that link one polymer chain to another. They can be covalent bonds or ionic bonds. When the term “cross-linking” is used in the synthetic polymer science field, it usually refers to the use of cross-links to promote a difference in the polymers’ physical properties. (info from wikipedia.org)

2.

Coupling Reaction:

Simply Speaking:

Coupling Reaction is the key for the adhesive strength between glass surface( metal surface, polymer sheet) and EVA Interlayer Film.

Professional Introduction:

A coupling reaction in organic chemistry is a catch-all term for a variety of reactions where two hydrocarbon fragments are coupled with the aid of a metal catalyst. In one important reaction type a main group organometallic compound of the type RM (R = organic fragment, M = main group centre) reacts with an organic halide of the type R’X with formation of a new carbon-carbon bond in the product R-R’ [1] (info from wikipedia.org)

3.

Polymer Mixing :

Simply Speaking:

Polymer Mixing is the procedure and formula of producing glass laminating EVA Ethylene Vinyl Acetate interlayer film.

Professional Introduction:

Mixing is important in to create new material properties, processability and cost-saving. Polymers are blended with other polymers to combine their properties and sometimes to even synergistically increase their physical characteristics. Various additives and reinforcing agents are mixed with polymers to improve mechanical performance and impart specific properties to the mixture.

CNC Glass Interlayer

www.cncglass.com www.c-n-c.com

[email protected] [email protected]

Product 1]Super Clear EVA Film for safety laminated glass

Product 2]Milky White EVA Film for safety laminated glass

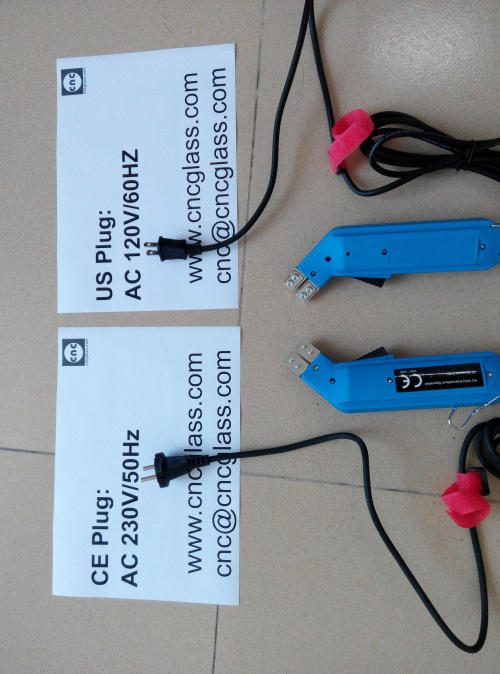

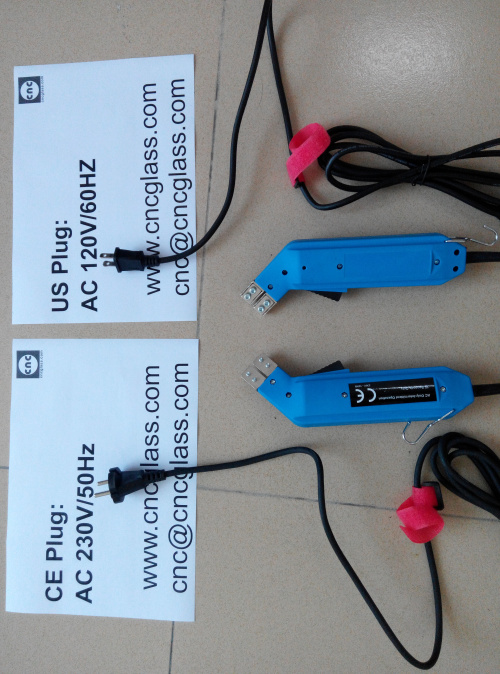

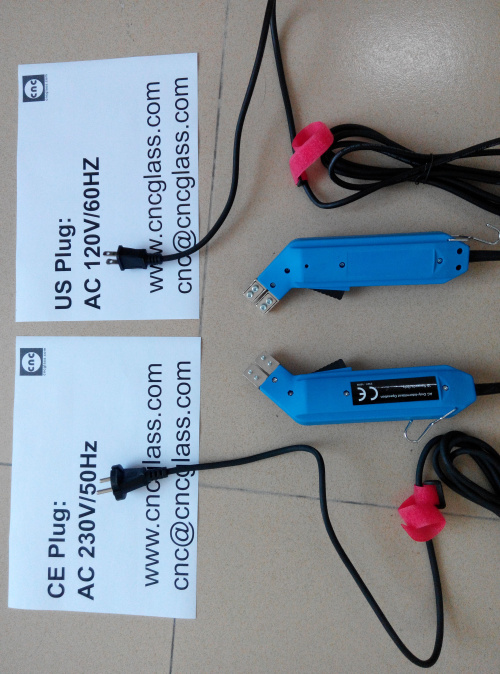

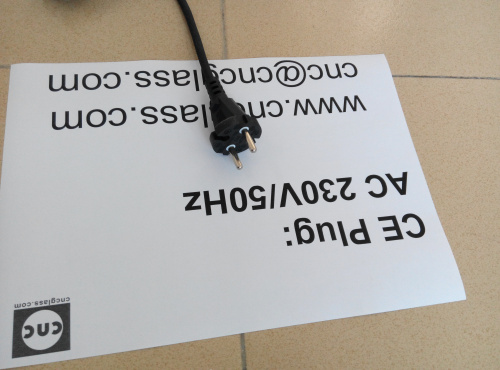

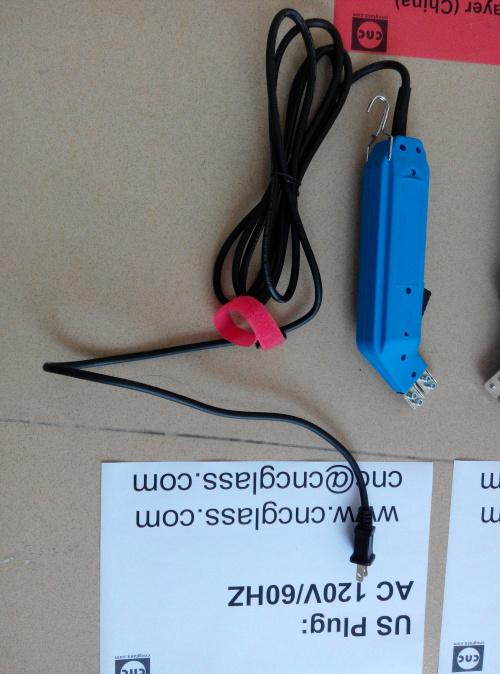

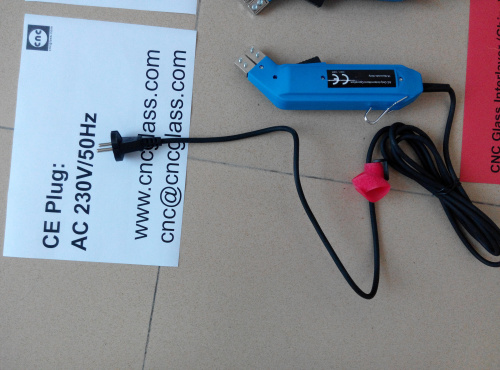

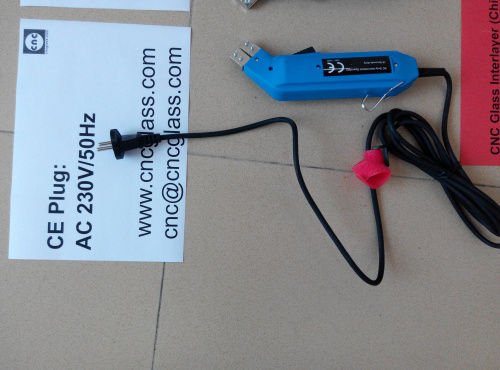

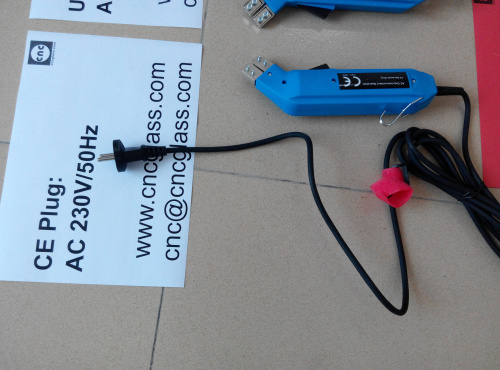

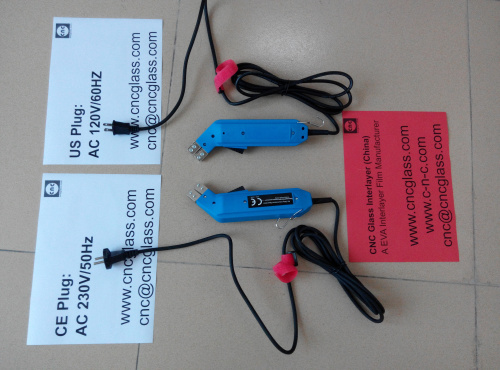

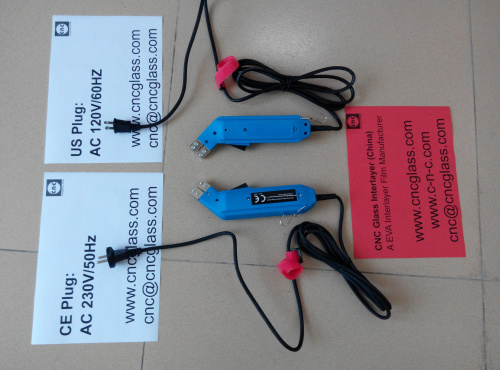

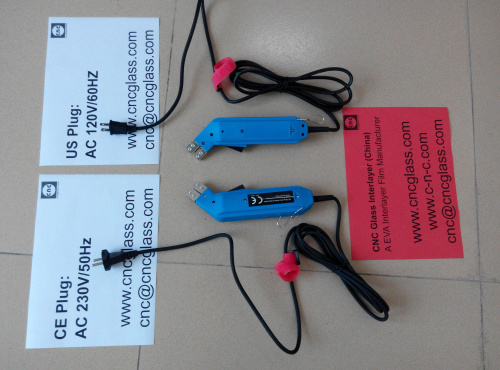

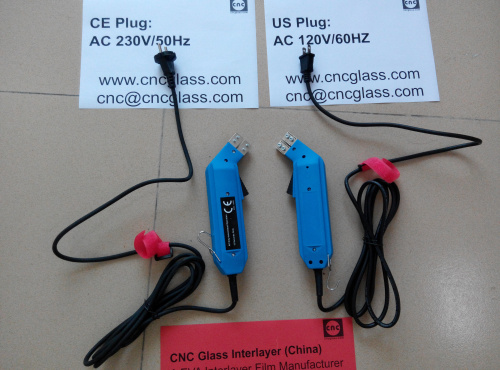

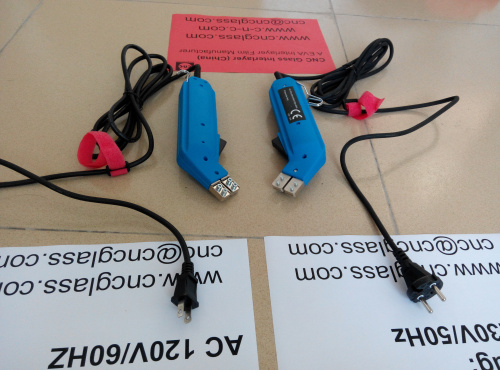

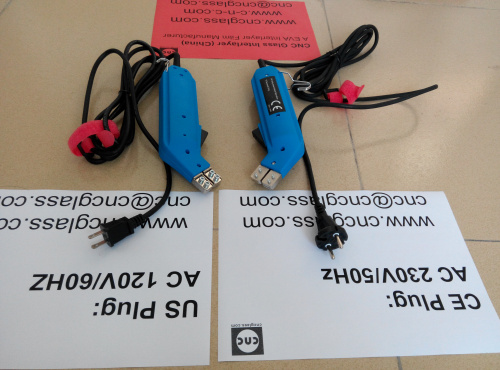

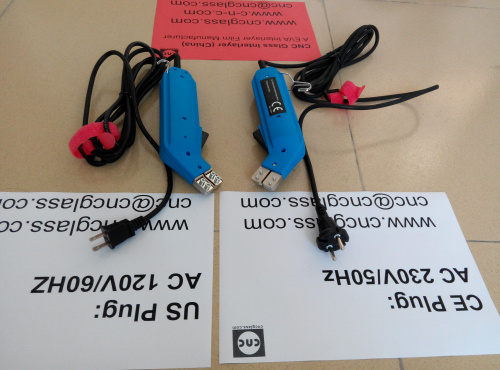

Product 3]Green Tape and Thermal Cleaning Cutter for EVA film safety laminated glass glazing